A good night’s sleep is just like a recipe for a cake, with many individual parts coming together to create a finished product – specifically a well-rested body that is full of energy for the day to come. Like any recipe, these ingredients must be added in certain quantities or the whole cake could be spoiled.

The complexity of the human spine continues to drive the scientific community, with ongoing research and study into just how varied the human body’s backbone can be and how this changes a person over the course of their life. As the spine changes to growth around it, this can affect the style of a person’s sleep and the type of mattress they find comfortable. It is a quest that may never be able to reach a singular, universal median but one which continues to be heavily invested into by three of Australia’s leading bedding manufacturers – Sealy of Australia, AH Beard and Sleepmaker.

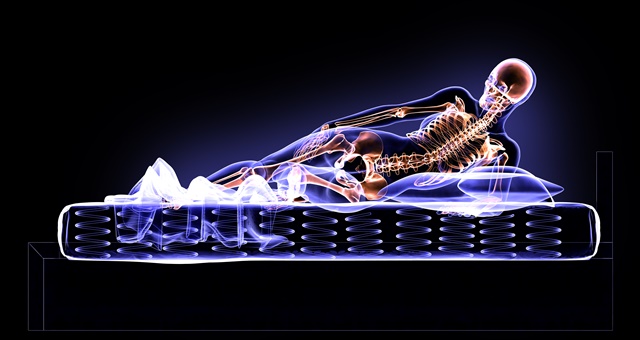

In 2017, Sealy Australia entered into a partnership with the Biomechanics and Spine Research Group (BSRG) at Queensland University of Technology in a project which, at present, will conclude later this year. The two parties have engaged to learn more about the critical factors which affect a person’s spinal comfort when lying down, with the ultimate goal of better understanding the biomechanical elements of a person’s body position when asleep. The project is being led by QUT Senior Research Fellow, Dr Paige Little, who brings extensive experience into spine biomechanics and computer modelling for biomedical application.

To complete the study, volunteer participants have been sourced to take part in sleep studies. These young and healthy adults consented to having their body shape, spinal alignment and perceived levels of comfort change over the course of an average sleep, lying on mattresses of varying stiffness.

Sealy of Australia Research and Development Manager, Daniel Green, said firmer beds are typically what people need, as plush bedding isn’t comfortable for a whole night or a longer stay.

“We want our mattresses to be supportive because we know from a lot of research over many years that if you’re not supported correctly while you sleep, you don’t sleep well and don’t wake up feeling great.

Sealy maintains a research team in Australia of around 12 people but also draws on the expertise of Tempur Sealy International in North Carolina, which has a further 75 in its research team. These teams are divided up into specialist areas such as heat management, sleep climate labs and durability.

“There has been ongoing research since 1950 so it’s probably more of a continuation for Sealy, which is built on a history of research, which was the first company to bring in orthopaedic surgeons and see how the bed aligns the body and led to the ‘no more morning back-ache’,” added Sealy National Marketing Manager, Wade Ganzer.

“I think the big shift in commercial bedding is because people are buying better beds for their homes now [so] the expectation of when you go to a hotel – a place primarily selling sleep – is that the bed is going to be superior quality, feel good and make you rest.

“A lot of luxury hotels are looking for that experience. Sleep and the bed is one of them. We’ve seen a massive growth in more premium bedding at luxury hotels.”

According to Sealy’s Sleep Census – last conducted in 2018 – the survey of more than 11,000 people found that getting enough sleep would make the biggest difference to their life. Better sleep rated higher in terms of importance than earning more money, working fewer hours and having an extra hour in the day. More than four in every five polled said they had trouble getting to sleep or staying asleep and of the 70% who admitted to waking up during the night, 35% of those said they struggled to get back to sleep.

“The interface and contact between the human body and the mattress is a key aspect of comfort and is one that is tested extensively,” Green wrote in Sealy’s Sleep Census results.

“To do this, Sealy utilises pressure mapping technologies to really understand how the mattress is interacting with the human body. High pressure on parts of the body is a key factor to tossing and turning throughout the night. The team of Sealy engineers work endlessly so that the right pressure relieving components can be introduced to their range of mattresses.

For A.H. Beard, its research and product development is driven primarily by cutting-edge technology and improvements into leading comfort foams and fills. According to the company’s history, A.H. Beard has been responsible for introducing a number of new innovations to the Australian bedding market, including the first chiropractic-approved mattress in its flagship King Koil range in 1970; gel mattresses in 2007 and the first iComfort smart mattress in 2016, with memory foam mattresses coming the following year. Its latest innovation for the accommodation industry, says Group Commercial Manager Peter Deveny, is phase-changing technology.

“We’ve just launched our new commercial range, and for the first time in the commercial environment, we’re offering a mattress with a phase-change material in the mattress panel.

“Phase-change material changes the ambient temperature and humidity of the bed. One of the biggest bugbears in hotel rooms is: guests get hot because it’s an enclosed space. People can’t sleep with the air on, can’t sleep with it off. So having a phase-change material in the mattress will allow the mattress to moderate the temperature in a sleeping environment.”

The company has also invested heavily in the development of pocket coil technology, which it says is the premium spring technology in the bedding industry. Pocket coils sees each individual spring enclosed in a sleeve to allow each spring to work independently, creating less partner disturbance, greater comfort and durability. Drawing on global research and tech innovation, A.H. Beard refined a version of this concept, dubbed Reflex, which incorporates extra support coils built in between the primary coils in the mattress.

“We now licence that technology,” Deveny added.

“We developed it, we designed it, and we now sell that to bedding companies all around the world. It’s the biggest selling part of our product range. In our retail business, reflex makes up the bulk of our sales. And that’s because of the wide coils for comfort, support and durability. And we’ve been offering them in commercial for six years. And so all of our really high-end hotels and premium hotels…that’s the product they buy.

A.H. Beard’s Reflex range beds are now in place across Crystalbrook Collection’s three new resorts in Cairns – Riley, Bailey and Flynn, the latter of which opened to guests a few weeks ago.

Deveny says he is seeing a shift in hotel companies opting for beds that are best practice, rather than setting brand standards and requiring a bedding manufacturer to adhere to defined restrictions.

“We’re seeing that demand now even from the global hotel brands, coming to businesses like us and instead of saying ‘Here are our brand-specs – you must adhere to this’, they’re coming to us and saying, ‘tell us what we can have.’”

In some markets around the world, raw materials that go into the construction of a mattress can periodically encounter hurdles in terms of availability, particularly as specifications change. One example of this is foam, which may present a problem to a global hotel brand seeking to adhere to a long-held brand standard which stipulates how its beds are made, what they contain and where these materials are sourced from.

For Australia, sourcing quality foam is rarely, if ever, a problem due to a strong manufacturing sector making mattress foams locally. However, while a clean and environmentally sustainable product is readily available, it can still be one of the most expensive parts of a mattress’ supply line.

In using major Australian bedding manufacturers, hotels have in turn been adopting distinctly Australian bed coverings, with design consultants recommending products exuding a local flavour and spirit.

According to HotelHome Design Director, Erin Coman-Beckett, hotels have moved away from international influences for their bed decoration, with more earthy tones such as a dusty red brown to represent Uluru or a bright blue for an Aussie summer sky. With domestic tourism set to lead the Australian industry back to prosperity, hotels are eager to remind local guests just how wonderful their backyard truly can be.

“Australian accommodation no longer needs to hang off international tends and influences such as ‘The Hampton look’, ‘Parisian style’ or ‘Caribbean influence,” says Coman-Beckett.

“Many visitors come a long way to experience our wonderful country and we should be offering them a taste of the Australian influence, which is unique.”

Another bedding manufacturer conducting their own research and development is Sleepmaker, which says the buzzword and hot-button issue around the bedding industry at the moment is on temperature control. To combat this, the company has developed what it describes as ‘climate tech quilting’ which is incorporated into the top layer of its beds, which provides for some moisture dissipation and helps the mattress breathe.

“So rather than a solid foam on the top of the bed, which can come sometimes cause body indentations and also generate some heat, the climate techs that we use in our foam and in the top panels of our bed actually dissipate the heat and lets the air flow through as well, to help sleep cooler,” said Sharnie Angel, National Business Manager for The Comfort Group, which manufactures the Sleepmaker brand.

One of Sleepmaker’s points of difference lie in its ‘Mira-coil’ spring system, which according to Angel are made from the strongest wire gauge in the market. This system draws on zoning technology which is designed to conform to the body and provide extra support to the hips and shoulders and to keep the body aligned while it sleeps.

“With all the keyboard warriors out there, the last thing you need is people comparing online and saying, ‘Oh yeah, it was really nice but my bed was not so nice’,” Angel added.

“When you turn on lights off, nothing else matters but your bed.”